Technical Feature: Tenneco FM-T88A

Submitted by:

Tenneco Inc.'s Powertrain business group has developed an innovative new material which delivers wear-resistant performance with greatly reduced Cobalt content, helping engine manufacturers mitigate the limited availability and price volatility of Cobalt.

The new material will be of great benefit in the demanding high temperature applications that typically rely on Cobalt to provide wear resistance in high temperature ranges, such as heavy-duty turbocharger wastegate bushings, EGR valves, and high-performance valve seats. Using an alternative sintered steel formulation, trials have shown that the Cobalt content in Tenneco's sintered materials can be reduced significantly, without compromising wear resistance.

Gian Maria Olivetti, Vice President Global Engineering at Tenneco Powertrain explains: 'Potential material shortages and controversy around Cobalt mining, coupled with extreme price volatility, mean we must reduce our dependence on Cobalt. While it remains the most effective material to combat wear in dry running valve seat applications and other components subjected to big temperature ranges, we have used our extensive experience in powder metallurgy to develop a low-Cobalt sintered formulation alternative that delivers similar wear properties to the best current materials.

The application temperatures for bushings in EGR valves, turbocharger wastegate systems or exhaust-gas valves can range from below 0°C up to 1000°C, and it is this wide variation that makes the tribology challenging, as Jens Wellmann, Tenneco Powertrain product manager for turbocharger components, explains. 'Especially in the lower temperature range up to ~400°C high-Cobalt materials can outperform the typical non-Cobalt materials. The first question we had to answer was:

What is the explanation for high-Cobalt material's low wear rates?' And the second question was: 'How much Cobalt is effectively needed to produce that effect?'

‘At 200°C FM-T88A displays a significantly reduced depth of wear compared to a cobalt-free material and is comparable to the results of the high-cobalt material, FM-T95A’

Tenneco's research started from two well-proven existing sintered products; FM-8100, an iron-based Cobalt-free sintered material, and FM-T95A, a Cobalt-based (54% Cobalt by weight) sintered material comparable to the cast materials used for tribological applications. Between these two extremes, a total of five materials with varied Cobalt content were evaluated for wear performance across a range of temperatures. Investigation of the worn specimen showed that the Cobalt-containing Tenneco sintered materials formed a wear-reducing tribolayer at lower temperatures than the Cobalt-free one. This early forming of a stable tribolayer gave the answer to the first question.

Comparing the samples, the same effect was examined on 17 to 35 per cent Cobalt materials, which provided the answer to question 2. Based on these results, a new material was developed, designated FM-T88A, a sintered steel with 17 per cent Cobalt, which met production and quality requirements, including the manufacturability and mixing of the metal powder, the sintering process, machinability and quality assurance.

To verify the results of the initial tests, collaborative trials were conducted with a major global vehicle manufacturer comparing the wear resistance of FM-T88A against series production materials.

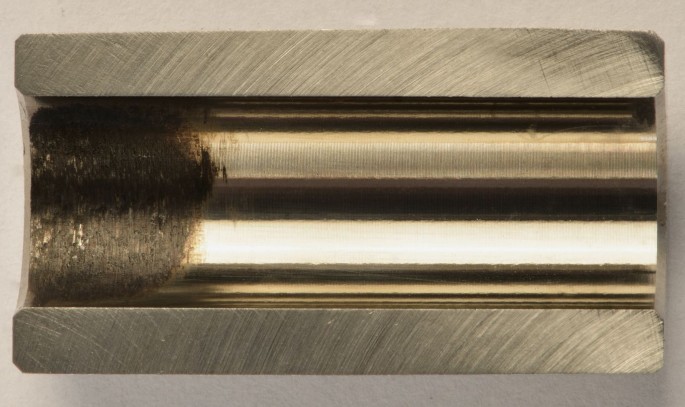

This was undertaken in a test rig which simulated the installation and loading of a turbocharger wastegate bushing running at temperatures of up to 800°C.

The results showed that at 200°C, FM-T88A displays a significantly reduced depth of wear compared to a Cobalt-free material and is at a comparable level of wear resistance to the high-Cobalt material, said Wellmann. 'At all other temperatures the new material's performance closely mirrored the high-Cobalt materials!

With 50 per cent of the Cobalt mined globally now used in batteries for electrified vehicle powertrains, demand for the material is growing year on year, said Olivetti.

'By minimising the levels of Cobalt used in our wear-resistant high temperature sintered materials, we can help our customers mitigate the limited availability and price volatility of cobalt while still delivering robust products.’

COBALT

Cobalt is a chemical element with the symbol Co and atomic number 27.

Apart from small deposits found in alloys of natural meteoric iron, it is found in the Earth’s crust only in chemically combined form. The free element that is produced by reductive smelting is a hard, lustrous, silver-grey metal.

Cobalt is primarily used in lithium-ion batteries and in electroplating, and in the manufacture of magnetic, wear-resistant and high-strength alloys.

Cobalt salts are used to impart blue and green colours in glass and ceramics and radioactive Cobalt is used in the treatment of cancer.

Today, some Cobalt is produced specifically from one of a number of ores, such as Cobaltite (CoAsS) but it is more usually produced as a by-product of Copper and Nickel mining. Most comes from the Democratic Republic of the Congo (DRC), currently accounting for more than 60 per cent of the global production, although there are also lesser sources in Russia, Australia, Cuba, Philippines, Madagascar, New Guinea, Canada, New Caledonia, South Africa and the USA.

An unfortunate and important consideration is that Cobalt mining has often been associated with child and slave labour, primarily in the mines of the DRC, and contact with Cobalt is associated with cancer, respiratory problems and skin complaints.

Technology companies seeking an ethical supply chain have consequently faced shortages, as well as increasing costs due to its rising requirements.

WHY IS COBALT USE IN THE INDUSTRY SO EXTENSIVE?

Wear-resistant materials that are effective at low to moderate temperatures, such as brass or plastic, lose their mechanical strength at high temperatures. Materials that are specifically developed for high temperatures succeed by generating oxidation products between the contact surfaces which act as a lubricating layer, but this mechanism doesn't work until the temperature exceeds a given threshold.

The trigger point for forming such a tribolayer is relatively low at ~200°C with Cobalt-base materials, providing high levels of abrasive and adhesive wear resistance combined with effective corrosion resistance, all the way up to temperatures of 1000°C or more. It's this extensive range which makes it so useful and why Cobalt has become the go-to solution for demanding dry sliding bush set-ups.

WHY TRY TO DEVELOP AN ALTERNATIVE TO COBALT?

With 50 per cent of the Cobalt mined globally now used for batteries in electrified vehicles and with the adoption of EVs growing significantly year-on-year, the demand is correspondingly growing, which is pushing up the price - Tenneco only sees the price of Cobalt rising.

Other factors, such as the controversy around Cobalt mining conditions and limited availability, all contribute to there being a strong case for finding an alternative. The challenge is to reduce the Cobalt content while still delivering robust products for applications such as shaft bushings for turbochargers and EGR valves.

The properties of Cobalt mean that automotive manufacturers have seen it as the 'problem solver' solution. If an alternative is developed, the benefits to the automotive industry will be significant. These include reduced component costs, a more stable price and long-term sustainability.

WHAT WAS THE PROCESS OF DEVELOPING A LOW-COBALT ALTERNATIVE?

The ‘five materials' used in the initial tests included cobalt content of 0, 8, 17,35 and 54 per cent. The tests were carried out in-house at Tenneco's Coventry facility in the UK.

HOW DID YOU VALIDATE THE NEW MATERIAL?

The collaborative trials conducted with a major global vehicle manufacturer comparing the wear resistance of FM-T88A against series production materials in a test rig, simulated the installation and loading of a turbocharger wastegate bushing. The wear test was carried out at six different temperature points (20, 100, 200, 300, 500 and 800°C) using new specimens in each case, with constant load application and each test running for 70 hours.

The results showed that at 200°C FM-T88A displays a significantly reduced wear compared to a Cobalt-free material and is comparable to the results of the high-Cobalt material, FM-T95A. At all other temperatures the new material's performance closely mirrored FM-T95A. Investigations showed that FM-T88A is forming a tribolayer like the high-Cobalt material, explaining the good performance.

HOW IS TENNECO CONTINUING ITS FURTHER DEVELOPMENT OF REDUCING COBALT CONTENT AND DEPENDENCE?

The development work by Tenneco demonstrates that, currently, it is not yet possible to eliminate the use of Cobalt from the manufacture of demanding shaft-in-bushing systems. However, testing of FM-T88A does prove that it is possible to optimise the metallurgy and manufacturing processes to enable the provision of comparable performance characteristics with a reduction in Cobalt.

Two further stages of development work are currently underway - test components produced using FM-T88A are currently being evaluated in a range of customer applications, and additional shaft materials are being assessed with a view to further exploration. Tenneco remains focused on the further development of materials in this key field.

ABOUT THE NEW TENNECO - THE FUTURE POWERTRAIN TECHNOLOGY COMPANY

Following Tenneco's expected separation to form two independent companies, an Aftermarket and Ride Performance company (DRIV™) as well as a new Powertrain Technology company, the new Tenneco will be one of the world's largest pure-play powertrain companies serving OE markets worldwide, with engineered solutions addressing fuel economy, power output, and criteria pollution requirements for gasoline, diesel and electrified powertrains. The new Tenneco would have 2019 revenues of $11.45 billion, serving light vehicle, commercial truck, off-highway and industrial markets.