Engine Feature: Koenigsegg TFG

Submitted by:

THE POWER OF THREE

Incredible performance and the potential for CO-neutral emissions from the latest hypercar, powered by an engine with just three cylinders and a displacement of only 2.0 litres...

Given all the concerns about the environment, fuel consumption and emissions, not to mention the ethical considerations in a world where a great many people are suffering from austerity, if not actually living on the poverty line or below, it's quite extraordinary just how many manufacturers are still designing and building hugely expensive and incredibly powerful hypercars, many capable of well over 200 mph.

Consider the likes of the McLaren F1 and Senna, Bugatti Veyron and Chiron, Mercedes-AMG Project ONE, Koenigsegg Agera RS, Porsche 918 Spyder, Ferrari La Ferrari, Aston Martin Valkyrie - all endowed with cutting-edge engineering and huge power outputs, all capable of phenomenal performance and mostly price-tagged above the million pound mark. That's a huge price to pay for something that is usually severely compromised in terms of everyday practicality - two-seaters with very limited luggage space - and even those with hybrid ICE / electric powertrains can hardly claim to be 'environmentally friendly Then along came the Koenigsegg Gemera, which recently made its debut. The world's first Mega-GT and Koenigsegg's first four-seater, it is undoubtedly an extreme megacar, but one that provides a spacious interior and comes with a high level of environmental consciousness along with its incredible performance.

Expected to go into production in early 2022, limited to just 300 examples, the Gemera not only seats four adults, provided with all creature comforts, as well as enough space for carryon luggage, but - capable of accelerating from 0 to 62 mph in less than two seconds and a top speed of 250 mph - it easily outperforms most two-seat megacars, both combustion engined and electric-powered.

That performance is achieved by the combination of a 2.0-litre three-cylinder internal combustion engine, and three electric motors - one for each rear wheel and one mounted on the crankshaft of the engine. These have a combined output of 800 kW or 1100 hp simultaneously, or 1400 hp when counted individually.

On top of that comes 600 hp at 7500 rpm and 600 Nm (between 2000 pm and 7000 rpm) from the twin-turbocharged 2.0-litre Freevalve engine that is the main focus of our attention here. The total output of the combined powertrain is a phenomenal 1700 hp or 1.27 MW of power and 3500 Nm of torque.

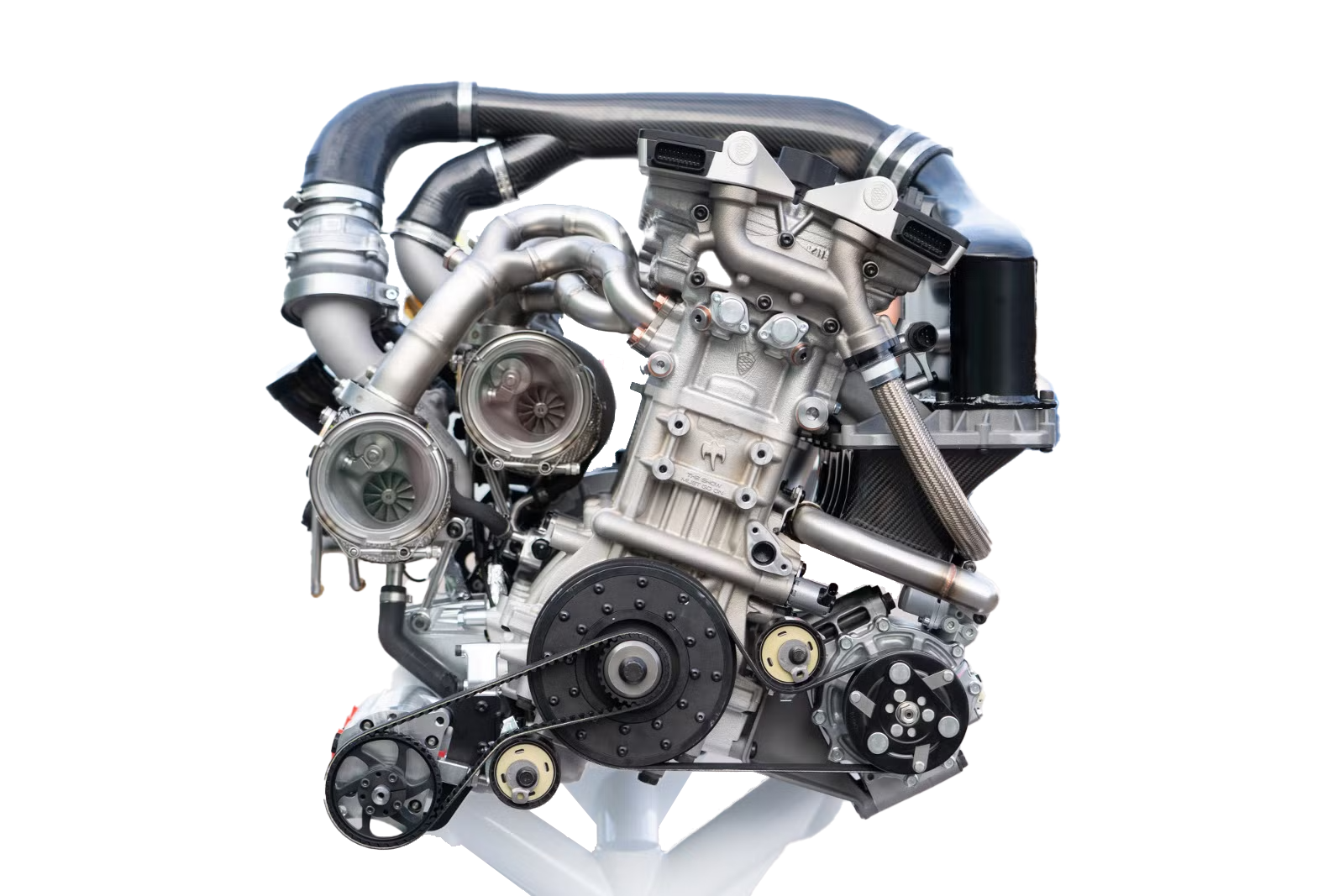

Designed and developed by the Swedish company Koenigsegg and its sister company Freevalve and almost whimsically nicknamed the 'Tiny Friendly Giant' (or TFG for short) this engine is described as 'a progressive outlook on the powertrains of tomorrow' as it offers a lighter, more efficient cradle-to-grave solution compared to any previous combustion engine.

Mounted longitudinally in the rear of the car, the three-cylinder TFG is physically very compact, considering its power and torque capabilities, with its power output of 600 hp and 600 Nm of torque more typically associated with something like a twin-turbo 6-litre V8 engine. A dry-sump oil system also helps to reduce the engine size while also providing perfect oil control during extreme dynamic driving. The complete long block weighs less than 70 kg and is compact enough that it could be fitted into a typical carry-on luggage case.

Quite apart from its inherent technical efficiency, the powertrain is designed so that, if plugged in and filled with second-generation (Gen 2.0) ethanol or a CO2, neutral methanol like Vulcanol or any mix thereof, it is at least as CO2-neutral as a pure electric car running on a 'good' electric source. Essentially, the TFG is future-proofed, given its extreme performance, reduced fuel consumption and lowered emissions.

In the meantime, until these second-generation renewable fuel sources become more readily available, the Gemera can also be run happily on E85 or even normal pump petrol.

At the core of the Gemera's Tiny Friendly Giant (TFG) engine is the revolutionary technology developed by Freevalve which allows independent and flexible control of the engine's intake and exhaust flows. Where previous engines with fully variable valve actuation used either electro-magnetic or electro-hydraulic control to open the poppet valves, Freevalve uses electro-hydraulic-pneumatic actuators combined with advanced sensor techniques. It not only offers a low CO2-footprint, but also substantially higher energy efficiency and lower emissions.

Freevalve technology also enables many other initiatives, such as a unique twin-turbo concept and unlimited cylinder de-activation, resulting in a reliable power output of 300 hp per litre combined with unparalleled flexibility.

With independent control of the intake and exhaust valves, the timing of intake and exhaust can be independently adjusted for any engine load criteria.

The system can determine how to operate the valves according to driving conditions, allowing a high degree of control over the engine in order to maximise power output, minimise fuel consumption or regulate emissions, providing both performance and environmental benefits.

Since there is no throttle, the Freevalves improve engine efficiency at part load by eliminating throttle losses, and by deactivating cylinders with Frequency Modulated Torque it further reduces fuel consumption to a level that is 15 to 20 per cent less than a typical modern four-cylinder 2.0-litre engine with direct injection and variable camshaft timing.

Freevalves are also capable of running the so-called Miller cycle, which is why the high boost twin-turbocharged TFG engine can run with a relatively high static compression ration of 9.5:1 and achieve both a high level of efficiency and high power output at the same time. All factors considered, the TFG is one of the most frugal and most powerful production engines in the world, for its size.

Freevalve also provides another important advantage, compared with traditional combustion engines with mechanical camshafts which give out most of their pollution during their first 20 or so seconds of cold start, due to cold cylinders, cold catalytic converters and poor fuel mixing at idle.

Only when the traditional engine heats up, do the cylinders and catalytic converters become warm and far less polluting, although there is still poor fuel mixing at idle. Given how good modern catalytic converters have become, these engines are virtually clean when warm and during normal driving.

The TFG overcomes two of the three issues directly at start-up, by heating up and provoking turbulence of the fuel mixture back and forth through the intake and exhaust valves. This much-improved cold combustion also leads to much faster catalytic converter heat up, reducing cold-start emission by around 60 per cent compared to an similar-sized traditional engine with conventional camshafts.

Even better is that, when running the TFG on renewable alcohol fuels, there are virtually no particulates produced and in many normal environments the TFG consumes and burns more particles from the surrounding air than it produces, thereby actually cleaning the air.

Using the best alternatives of alcohol fuels there is even the possibility for net-zero or CO, negative emissions.

Although alcohol fuels maximise performance, as they provide greater internal cooling effects and have higher octane compared to petrol, they are more difficult to vaporise than petrol when cold. Therefore, petrol is usually added to the alcohol during severe cold starts to solve the problem.

The Freevalve system overcomes this cold start issue by utilising a pre-start heating mode for the initial cranking and first combustion. One intake valve is used and opened late with low lift for maximum turbulence and vaporisation.

Cylinder deactivation is applied to increase the amount of air and fuel in each combustion during starting and warm-up. Internal exhaust gas recirculation (EGR) is activated in the following combustion cycles, using hot residuals from the previous combustion to vaporise the fuel. Additionally, the engine's variable compression ratio is adjusted by the Miller cycle.

Furthermore, the TFG can be turned multiple times before switching on the ignition, using the piston to pump the air back and forth to the inlet in a 'heating mode' cycle, with the result that the inlet air temperature is increased by 30°C in 10 cycles, taking about 2 seconds, without any need to add petrol to the fuel or starting cycle, making the TFG independent of fossil fuel use in any climate.

The TFG's Freevalve system allows full control of the combustion cycle, affording a degree of control and reliability that is way beyond that of any other variable valve actuation system.

Both the intake and exhaust valves can be opened and closed at any desired crankshaft angle and to any desired lift height. This flexibility enables the TFG to achieve low fuel consumption and emission figures, while still delivering massive torque and power.

The Freevalve system also made it possible to create a patent-pending, simplified two-stage turbo system.

Essentially, one turbo is connected to three exhaust valves - one from each cylinder. The second turbo is connected to the other three exhaust valves. During low rpm and part to high load, all exhaust gasses are pushed to only one turbo, by only opening one exhaust valve per cylinder - thereby doubling the exhaust gases to that turbine. When adequate boost is reached, the second exhaust valve is opened to start the second turbo.

The result is a three-cylinder 2.0-litre engine that develops 400 Nm of torque from just 1700 rpm and produces maximum torque of 600 Nm, making the TFG the most powerful engine per cylinder and volume to date, putting it way ahead of any other current production three-cylinder engine.

'Ultimate performance has belonged to the world of two-seaters with very limited luggage space - until now. The Gemera is a completely new category of car where extreme megacar meets spacious interior and ultimate environmental consciousness. We call it a Mega-GT.’

-- CEO and founder Christian von Koenigsegg.

KOENIGSEGG GEMERA SPECIFICATION

ENGINE

Koenigsegg Tiny Friendly Giant (TFG) twin-turbo Freevalve 3-cylinder 2.0- litre engine

Displacement: 1988 cc

Bore: 95mm Stroke: 93.5 mm

Compression ratio: 9.5:1

Power output: 600 hp (440 kW) at 7500 rpm (red line at 8500 rpm)

Torque: 600 Nm (442.5 lb.ft) from 2000 rpm to 7000 rpm.

Lubrication: Dry sump

Engine weight: 70 kg

E-motors: Three electric motors - one for each rear wheel with 500 hp and 1000 Nm each and one E-motor on the crankshaft with 400 hp and 500 Nm to power the front wheels (together with the ICE)

ENGINE MANAGEMENT

Koenigsegg engine control module.

Flex fuel capability including E100, Methanol and sun fuel.

High power ion sensing coil-on-plug ignition system.

POWER OUTPUT

Total output: 1700 hp / 3500 Nm, including Hydracoup

Max wheel torque: 11,000 Nm at ICE 4000 гр

Electric power: 800 kW (1100 hp) combined (counting E-motors separately - 1400 hp)

Performance: 0-100 kph (0-62 mph) in 1.9 secs. Top speed: 250 mph (400 kph)

RANGE

ICE only range: up to 950 km.

Electric range: up to 50 km.

Total range: up to 1000 km

TRANSMISSION

Mid-mounted Koenigsegg ICE + E-motor Hydracoup Direct Drive transmission powering the front axle. Front axle has torque vectoring capability and can be disconnected to save energy in EV-only mode. Rear axle: Independent E-motors with independent transmissions enabling torque vectoring and reverse. Rear transmissions equipped with wet clutches for decoupling, for range mode.

CHASSIS

Carbon-fibre monocoque with wheel to wheel stiffness 40 KNm. Front and rear aluminium sub-frames.

BODY SHELL

B-pillarless, two-door coupe with fully accessible four-seat interior. Carbon fibre body panels. Visible carbon fibre on front and side splitters and venturi.

STEERING

Rack and pinion electric power-assisted steering, with active rear wheel steering.

SUSPENSION

Double wishbones and adjustable gas-hydraulic shock absorbers, with electronically adjustable ride height.

Adjustable lightweight anti-roll bars front and rear.

ELECTRONIC STABILITY / TRACTION CONTROL

Koenigsegg Electronic Stability Control (KES).

Traction control: Wet / normal / track

ASSISTED DRIVING

Autonomous Driving Level 2 ADAS, adaptive cruise control, Lane assist, Park assist, Surround-view cameras.

BRAKES

Ventilated ceramic discs,

Front: 410 mm diameter, 38 mm

6-piston. Rear: 395 mm diameter, 32 mm 4-piston. Koenigsegg callipers with ceramic pistons.

Electric brake booster and ABS.

WHEELS / TYRES

Koenigsegg Aircore carbon fibre wheels with centre locking (optional)

Front: 10.5 x 21-inch

Rear: 11.5 x 22-inch with Michelin Pilot Sport 4S (or optional Michelin Cup R3)

Front: 295/30 ZR21

Rear: 317/30 ZR22

DIMENSIONS

Length: 4975 mm

Width: 1988 mm

Height: 1295 mm

Ride height: 117 mm front (+35 mm) / 117 mm rear

Wheelbase: 3000 mm

Kerb weight: 1850 kg

Fuel capacity: 75 litres

Load volume (rear and front): 200 litres.